Vanzetti Engineering presents the new ESK-IMO series of retractable submerged pumps, which are used in Small-Scale LNG Terminals and as Emergency pumps or Cargo/Stripping pumps in the marine sector. The ESK-IMO pumps offer the advantage of easy maintenance without the need for tank draining and reclamation.

Cavallerleone, March 2024 – Vanzetti Engineering is expanding its product portfolio by introducing a new family of submerged pumps, the ESK-IMO retractable series with flow rates from 70 m3/hr up to 500 m3/hr and a head of up to 240m.

As the entire hydraulic and mechanical part derives from the ARTIKA Series, the ESK-IMO pump inherits the reliability and quality of a product that is already acknowledged and well-established in the market.

The ESK-IMO Series is used in the industrial field in Small-scale terminals with a capacity of <1 MTPA, million tonnes per year and in the marine field where the retractable pumps are used as Emergency pumps or Cargo/Stripping pumps for emptying tanks in the event of malfunction and/or necessary maintenance on the main pumps.

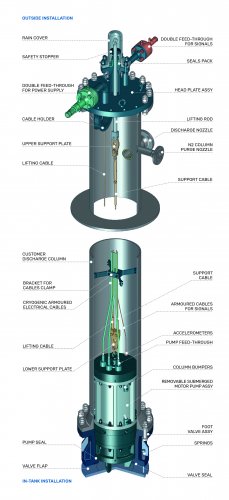

In contrast to the ARTIKA Series, which is mounted directly at the bottom of the tank or inside a cryostat, the ESK-IMO retractable pump is installed inside a column that is isolated from the rest of the tank by a foot valve. In this way, the liquefied natural gas remains confined in the tank outside the column, allowing the pump to be removed by opening a cover at the top of the column.

Vanzetti Engineering offers the new retractable submerged pump series with all the accessories required for its operation: the foot valve, the column cover, the cables required to lift the pump and remove it from the tank, and the electrical connectors. As an optional extra, a vibration monitoring system is also available to display and signal any malfunction alarms.

A special feature of the ESK-IMO retractable pump is that it does not require the tank to be emptied for maintenance.This is an important added value considering that the tanks of Small Scale LNG Terminals are subject to very long maintenance intervals (over twenty-five years). As the maintenance interval of the pump is generally shorter than that of the tank, it is a huge advantage to be able to remove the pump and carry out maintenance without taking the tank out of service because it makes the process quicker and easier for both the user and the terminal itself. In addition, all potential related risks are thus avoided.

In the marine sector, the ESK-IMO Series allows for greater flexibility in maintenance activities, making it possible to empty atmospheric tanks (operating at a pressure of less than 1 bar) in order to service the tank itself or the installed pumps. Moreover, the ESK-IMO pump does not require a large space above the tank – a feature that is compatible with environments normally found below deck – to be extracted from the column.

The Small Scale LNG Terminal and marine markets are experiencing unprecedented growth, with particular emphasis in the Americas and South East Asia regions. These segments are emerging as key drivers in the transformation of the global energy and maritime landscape. With increasing demand for alternative energy and growing pressure to reduce emissions, terminals are proving to be a flexible solution that can bring LNG to where it is needed, especially in industrial, commercial, civil and shipping contexts. In parallel, the LNG shipping market is experiencing significant growth. LNG-fuelled ships offer an alternative to traditional fuel, helping to reduce emissions to comply with increasingly stringent regulations, in turn generating growing demand for port infrastructure and dedicated terminals.

This virtuous circle is fuelling rapid and sustained growth in both sectors, with prospects for further expansion in the near future, and the new ESK-IMO Series fits strategically into this context.

Vanzetti Engineering

Established in 1984, Vanzetti Engineering S.p.A. is an Italian company active in the design and manufacture of cryogenic equipment for Liquefied Natural Gas (LNG) and air gases. With its range of products, Vanzetti Engineering is able to cover downstream applications in the LNG chain.

Opened in 2015, its new 12,000 m2 plant houses its cryogenic pump and skid production processing departments, and has allowed for a considerable increase in the company’s production capacity.

Thanks to the skills acquired over the years, Vanzetti Engineering has developed a complete range of cryogenic pumps and components for its main business sectors: Marine, Automotive and Industrial. Vanzetti Engineering’s solutions are used in many types of applications, including: fuel systems for marine engines and ship refuelling; LNG/L-CNG refuelling stations; transfer systems from road trailers and stationary storage tanks; satellite stations with power supply and support to the gas pipeline network, including power generation plants; medium and high pressure filling of air gas cylinders (nitrogen, argon, oxygen) for industrial, food and medical applications.

www.vanzettiengineering.com