A Synergy That Sets New Standards

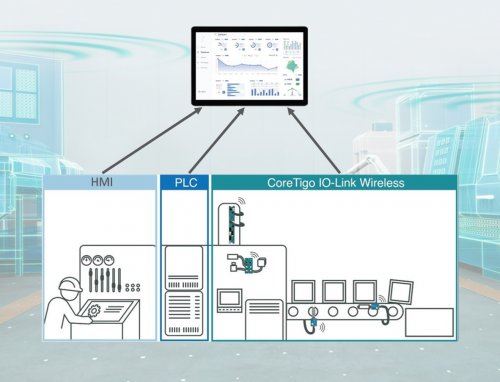

The collaboration of CoreTigo and Raven creates new, much needed abilities in the manufacturing landscape by combining the two companies’ strengths. CoreTigo’s IO-Link Wireless technology is known for transforming production monitoring, overcoming traditional communication obstacles through the industrial-grade wireless solution. This offers accessibility even in the most challenging and harsh factory environments. The key to this is CoreTigo’s ability to retrofit legacy machines and components with IO-Link Wireless connectivity, without disrupting the production line design or requiring special feedback devices or sensors.

With Raven’s state-of-the-art OEE and production tracking software, integrated seamlessly with CoreTigo’s technology, manufacturers gain a complete, contextual overview of production inefficiencies and losses. Raven analyzes data from operators and existing manufacturing systems to identify how people and machines spend their time on the production floor, accounting for 100% of production time. With actionable insights from combined human and machine sources, manufacturers are empowered to optimize production processes, reduce downtime and boost revenue generation.

A New Era in Manufacturing

The combination of technologies and offerings by CoreTigo and Raven enables a number of key benefits, including:

● Unique Combination: This partnership is the first of its kind to offer vast data-gathering capabilities, integrated with advanced analytics tools. These result in optimization opportunities, never before seen in the industrial landscape.

● Proven Results: CoreTigo’s and Raven’s technologies both present a strong track record of valuable outcomes to customers across industries. Combined, these have shown even greater value for early adaptor customers, including a leading USA-based pharmaceutical manufacturer.

● Agility and Reliability: IO-Link Wireless presents capabilities on par with wired industrial communication protocols, including a low Packet Error Rate (PER), deterministic nature, 5 msec latency, and more.

● Scalability: Designed for industrial purposes, and not being restrained by wires, IO-Link Wireless supports a large number of devices, while maintaining all above capabilities.

“The collaboration with CoreTigo marks a milestone in our journey towards offering a holistic digital solution in manufacturing,” states Martin Cloake, Co-Founder and CEO at Raven. “This integration empowers manufacturers to not only collect data, but also to act on it in unprecedented ways.”

Affirming this sentiment, Reid Schook, President at CoreTigo, said, “We are delighted to collaborate with Raven to bring our technology to the market in a comprehensive solution. Together, we can provide a powerful tool for manufacturers to improve their productivity and efficiency, with access to data from anywhere on the production line.”

Manufacturers looking to level up and maximize their shop floor performance can learn more or book a personalized demo by visiting the CoreTigo website and Raven.ai website, or view the Product Guide here.

About Raven

Raven is a leader in manufacturing technology, specialized in enhancing operational performance and empowering frontline teams with its advanced OEE and automated contextualization software. By synthesizing data from both machine and operator inputs, Raven delivers a complete, real-time view of production events — accounting for 100% of production time and losses. This approach ensures a comprehensive understanding of all elements affecting production time and OEE losses. Serving a global clientele across diverse sectors such as Discrete Manufacturing, Food and Beverage, Pharmaceuticals, Agri-Food, and Healthcare, Raven is dedicated to driving efficiency in manufacturing processes. Learn more about Raven at raven.ai.

About CoreTigo

CoreTigo enables faster and more flexible manufacturing by providing high-performance machine digitalization, wireless connectivity and edge solutions for machine builders, system integrators and industrial equipment manufacturers. CoreTigo’s products enable the design and retrofit of machines and production lines that were not possible before. These solutions increase flexibility, adaptivity and modularity, resulting in cost effectiveness, increased productivity and downtime reduction. Embraced by industrial leaders, CoreTigo’s solutions are based on the IO-Link Wireless global standard, which is fit for harsh factory environments and motion control applications, providing the most reliable wireless connectivity for millions of sensors, actuators and industrial devices worldwide.

About IO-Link Wireless

IO-Link Wireless is a deterministic, low latency (5 msec) and low synchronization rates (10’s of microseconds), highly-reliable and scalable universal wireless communication protocol. Based on the IO-Link IEC 61131-9 standard, it is designed specifically for factory automation, coexisting with other networks – both wired and wireless.

CoreTigo

CoreTigo enables faster and more flexible manufacturing by providing high-performance machine digitalization, wireless connectivity and edge solutions for machine builders, system integrators and industrial equipment manufacturers. CoreTigo’s products enable the design and retrofit of machines and production lines that were not possible before. These solutions increase flexibility, adaptivity and modularity, resulting in cost effectiveness, increased productivity and downtime reduction. Embraced by industrial leaders, CoreTigo’s solutions are based on the IO-Link Wireless global standard, which is fit for harsh factory environments and motion control applications, providing the most reliable wireless connectivity for millions of sensors, actuators and industrial devices worldwide.