Technical cleanliness as a quality characteristic is gaining more and more in importance. Especially in electromobility applications, the relationship between technical cleanliness and leak-tightness plays a vital role in ensuring that fastenings perform reliably.

Figure 1: Tightness and cleanliness considerations are often focussed on leak-tight applications like battery enclosures, final assembly or installation.

“Clean & tight” refers to the essential technical relationship that forms the basis for leak-tight fastening solutions such as those demanded by the electromobility industry. ARNOLD UMFORMTECHNIK, the Forchtenberg-based manufacturer of fastening solutions, undertakes research into the fundamentals of achieving tightness and cleanliness, specifies applications and analyses the factors influencing the system. ARNOLD has been active in the field of technical cleanliness for many years and was one of the pioneers in this area. The company is keen to raise awareness of the fact that each specific tightness requirement must go hand-in-hand with a defined level of cleanliness.

Requirements for technical cleanliness

The demand for technical cleanliness first originated in the automotive industry. Today, generally applicable regulations define a standardized framework for the implementation of technical cleanliness, such as VDA 19.1 for testing technical cleanliness, VDA 19.2 for technical cleanliness in assembly, ISO 16.2.3.2 and a guideline on technical cleanliness for the electronics industry from the German Electrical and Electronic Manufacturers’ Association (ZVEI).

ARNOLD UMFORMTECHNIK has a wide range of equipment available for testing tightness and technical cleanliness. These include two leak test benches that use test gas: a mass spectrometry system that uses helium as the test medium and a differential pressure method that uses air as the test medium. A further leak test stand, which uses water as the test medium and can also be used for IPX7 verification.

Figure 2: At ARNOLD UMFORMTECHNIK, two test benches are available for leak testing using test gas measurements, and a leak test bench that uses water as a test medium and is capable of IPX7 verification.

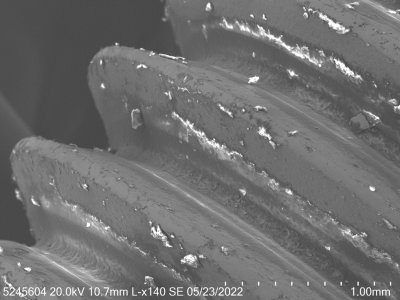

For the cleanliness analysis, it is important to identify the contaminant particles actually present on the components. At ARNOLD, the contaminant particles are removed from the component in an extraction cabinet and collected. Various methods are then used to perform the required evaluation. For example, an optical microscope can be used to measure the length and width of the contaminating particles and classify them as metallic-bright or non metallic-bright. The mass of the particles can be measured using a laboratory balance. Arnold has recently acquired a scanning electron microscope. This can be used to determine the precise chemical composition of a contaminant particle. Conclusions can also be drawn about the source of the defect. A residual magnetism tester is also available.

Solutions for individual customer applications

The “clean & tight” concept is important for many fastening use cases. This is especially true for leak-tight applications such as battery enclosures, final assembly or installation. It is also very important in the electronics industry, for example when circuit traces are close together. Clean connecting elements are also essential for oil-feeding systems and sensor technology for autonomous vehicles. Complex multifunctional and multi-stage components – the Conform Next parts manufactured by ARNOLD – can also be included in these cleanliness assessments.

Figure 4: Arnold has recently acquired a scanning electron microscope. This can be used to determine the precise chemical composition of a contaminant particle. Conclusions can also be drawn about the source of the defect.

The aim of the Clean & Tight tests at ARNOLD UMFORMTECHNIK is to ensure a reliable assessment of the tightness of the fasteners in relation to customer applications. In addition to determining how tight the components are, long-term influences such as corrosion or environmental influences should also be evaluated. As a result of all these tests, it is possible to determine which fastening solution meets which tightness requirements.

The Cleancon concept developed and patented by Arnold guarantees technical cleanliness across all process steps.

All pictures: ARNOLD UMFORMTECHNIK

Carl-Arnold-Str. 25

74670 Forchtenberg-Ernsbach

Wanke Magdalini

Phone : +49 7947 821-2833

Fax : NA

Magdalini.Wanke@arnold-fastening.com